First-Year Students Model CAD Skills, Fracture Fixation Devices

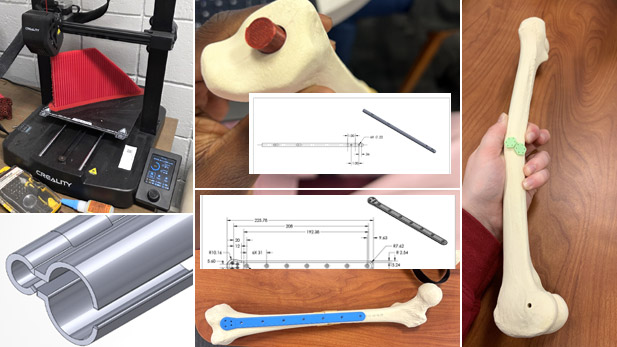

First-year students in Nicole Ramo's BE 118 design course gained industry-relevant experience by creating digital models of devices to help heal bone fractures.

First-year biomedical engineering students had a bone to pick for their final fall quarter project — literally. Tasked with modeling fracture fixation devices — hardware, such as plates, screws, or nails, used to reattach bones in cases of severe breaks — for replicas of fractured bones, the students gained hands-on, industry-relevant experience in Computer-Aided Design (CAD) and SolidWorks during their first quarter on campus.

Nicole Ramo, PhD, an assistant professor of biology and biomedical engineering, joined the Rose-Hulman faculty in fall 2025 and developed the innovative project for BE 118: Design Thinking and Communication.

"I wanted something that was clinically relevant and tangible and accessible to students who had been out of high school for just a couple of months," Ramo said.

Students discussed their experiences with broken bones and how they were treated, using that as a launching point to researching existing fracture fixation devices available in medical markets. With Ramo's guidance, the students learned the basics of patient-specific modeling by using calipers to measure the exact specifications of each fracture model.

They then translated their designed solutions into a 3D computer model and utilized campus resources, including the Biology & Biomedical Engineering Department shop, to 3D print tangible representations of their devices to fit neatly into the bone fracture replicas.

"There were some students who took direct inspiration from what's currently on the market…but we also had students who came up with their own unique contraption of holding the bone fragments together," Ramo said.

Marlee Armstrong, a biomedical engineering major, learned from existing techniques to design a rod with holes to be screwed into a transverse femur fracture for her project.

"The course was very fun and interactive," Armstrong said. "From that project, I learned how to do research and create something that could be used in a real-life situation."

Biomedical engineering major Rebecca Peterson also valued the context that BE 118 added to her skills. For her project, she designed hexagonal plates that were small and versatile enough to enable easy positioning but still durable enough to stabilize a femoral fracture during recovery.

"One of the most important things I learned was the importance of being able to handle and measure a real-life reference object since it is difficult to conceptualize the measurements in SolidWorks," she said.

That connection to the biomedical engineering field and introduction to the engineering design process was exactly why Ramo designed the project. She modeled the experience off a similar concept she had implemented during her instructional postdoctoral fellowship at a different institution, where students did not get solid modeling experience until nearly the end of their sophomore year.

"I've been really, really impressed with the (Rose-Hulman) students," Ramo said. "They're actually thinking about this, and have really thoughtful, insightful questions. I had to be on my game to anticipate the types of questions they might have."

She noted that, while many of the students came into the course with no prior experience in SolidWorks, they learned to model designs toward which they felt genuine pride. Several of the students remarked in their final reflections that they were eager to show their model to their families when they visited home for the holidays.

Alexei Simon, a biomedical engineering major with a minor in biomathematics, was one such student. She created a model of an intramedullary nail, which is commonly used to treat fractures that split the entire femur.

"BE 118 was an amazing experience to get into the world of CAD while learning the basics of medical-focused design," she said. "It provided a very safe space to ask any number of questions that I was confused about."

Ramo sought to set students up for success by building foundational skills even beyond SolidWorks, approaching faculty who taught upper-level design courses and asking what knowledge would behoove students to develop early. She incorporated that feedback into the course structure, building modules to discuss imposter syndrome, plagiarism, and ethical research. She also helped the BE 118 students complete training required to gain access to some of the tools of the Branam and Kremer Innovation Centers.

Ramo wanted the students to gain an appreciation for the opportunities available in their major, implementing an activity where she asked students to research and develop questions for employers hiring first-year students for biomedical engineering internships at the Fall Career Fair. Ramo also invited her students to presentations of both sophomore and senior level biomedical engineering design projects.

"Over the course of the class, I grew a lot by learning how to think like a designer," said Israel Tioua, a biomedical engineering major who designed an internal fixation nail for a high school varsity soccer player's injury.

Tioua added, "I learned how to define users and stakeholders, write problem statements, and turn ideas into designs."

The course also aimed to enhance student learning by using specifications-based (or "specs") grading. Designed to remove the temptation to chase specific numerical point values, specs grading instead focuses on meaningful feedback, offering students opportunities to redo assignments and to understand how they can improve on future projects.

Peterson is already applying that feedback and knowledge to other endeavors.

"I am proud to say that I now hone my capabilities by using CAD on parts for the Rose Grand Prix Engineering team," she said. "It is encouraging to be able to use the things I learned in class in the real world — and without using a textbook."

Design thinking and problem solving are the marrow of the biomedical engineering curriculum, with at least one design-based course required each quarter. The SolidWorks skills and accompanying confidence built through BE 118 and the fracture fixation project jointly cast a strong foundation for students at the start of their biomedical engineering journeys.