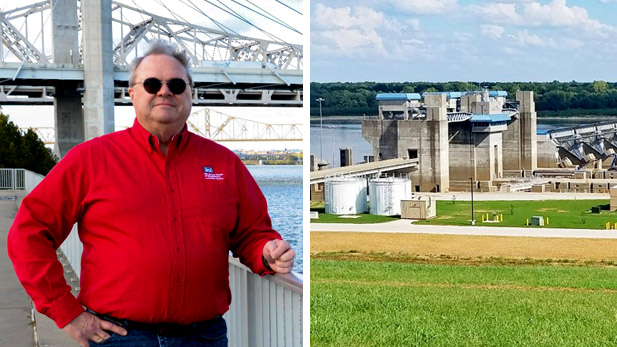

Alumnus Dewey Rissler Helps Keep Traffic Flowing on Ohio River

The Ohio River’s Olmsted Locks and Dam project is the crown jewel of civil engineering alumnus Dewey Rissler’s award-winning 40-year career as an engineer with the U.S. Corps of Engineers’ Louisville District office.

It took more than 30 years of project planning and execution for 1977 civil engineering alumnus Dewey Rissler and an army of engineers, technicians and workers from across the world to complete the $3 billion Olmsted Locks and Dam on the Lower Ohio River between Illinois and Kentucky – the largest civil works project undertaken by the U.S. Army Corps of Engineers since building the Panama Canal.

First, the mission itself was huge. Antiquated Locks and Dams 52 and 53 have been replaced with one structure. The dam was built of massive precast-concrete components built onshore, moved to their required locations, and then installed on the river bottom within extremely tight tolerances.

And, within the constant flow of one of America’s most important rivers.

Lock and Dam 52 is located near Paducah, Kentucky, while Lock and Dam 53 is approximately 19 miles upstream from the Ohio River’s convergence with the Mississippi River, 31 miles downstream from the mouth of the Tennessee River and 41 miles downstream from the mouth of the Cumberland River. Water elevations in this area can change as much as 50 or more feet throughout the year making normal construction activities difficult. When the water level is high enough for the passage of barge traffic Olmsted’s wickets lay on the bottom of the river.

Approximately 90 million tons of commodities annually pass through this section of the river – known as the “Hub of the Inland Waterway System.” That’s more than any other area of the country.

Rissler has been the project’s fourth and possibly last manager – the crowning jewel of an award-winning 40-year career of managing and constructing projects for the Army Corps of Engineers’ Louisville District office. His association with the project began in 2016 with a temporary assignment as the project manager for four months.

“I loved the sheer magnitude of the project and dam construction,” he says. “When the permanent project manager position came open, I moved in.”

The project, originally conceived in the 1980’s with a feasibility study, involved the construction of two 1,200-foot lock chambers, five 110-foot wide Tainter gates and a 1,400-foot wicket dam consisting of 140 10-feet-wide by 28- feet-tall steel wickets. These additions are replacing the old locks as well as the nearby wicket dams and other marine and land-based structures.

All this work took more than 45 million hours of labor.

Part of this herculean effort had the Army Corps of Engineers and its partners constructing the dam In-The-Wet, an innovative process where the structure’s massive precast-concrete components were designed and built onshore, then floated to their required locations, and placed – like massive Lego blocks – underwater to their desired location on top of prepared pilings on the river bottom. Once in place, the void under the sections was filled with concrete to create a solid mass.

Completing the project has been demolition of the old locks and dams 52 and 53, along with the facilities originally used to house the operations personnel and final restoration of the Olmsted construction site.

“My job was to make sure we didn’t run out of fuel (momentum),” states Rissler. “The hardest part (once the dam was operational) was keeping people focused on completing the remaining project work over the next three years.”

The Olmsted Locks and Dam project earned the 2020 Outstanding Civil Engineering Achievement Honor Award from the American Society of Civil Engineers, with Rissler representing the Louisville District office at the awards ceremony. He also wrote an article about the project’s engineering and construction innovations for ASCE’s Civil Engineering magazine (June 2019 issue).

Unseasonably high water in the Ohio River delayed wrapping up the project’s final details after it went operational in August of 2018, four years ahead of the planned schedule. Rissler helped successfully secured $65 million in additional funding to finish all remaining work, which is now planned to be complete next year, also four years ahead of schedule.

Another challenge was monitoring the construction area for endangered mussels.

Rissler is used to handling such challenges. The Army Corps of Engineers’ Louisville District supervises all military construction across Ohio, Indiana, Illinois, Kentucky, and Michigan, and maintains navigation on the lower Ohio River. This includes operating and maintaining nine locks and dams (seven on the Ohio River and two on Kentucky’s Green River) and 17 flood risk management lake projects in Kentucky, Indiana and Ohio.

The Air Force’s consolidation of several facilities under the federal government’s 2005 Base Relocation and Closure (BRAC) Commission had Rissler managing the $200 million construction of eight different projects at the Wright-Patterson Air Force Base in Dayton, Ohio. This endeavor saved considerable time and cost – earning Rissler recognition as the Air Force’s 2010 Civilian Project Manager of the Year.

“It has been a rewarding career. Along the way I’ve met a lot of great people and seen a lot of interesting things. I have stood in the middle of the world’s largest vacuum chamber at a NASA research facility and had other adventures,” he says. “Retirement is approaching. I don’t know what the future holds, but I’m sure it will be fun.”

---------

INSIDE THE PROJECT

- Largest civil works project by the U.S. Army of Corps of Engineers since the Panama Canal

- $3 billion total cost

- Culminated 30 years of engineering innovation and ingenuity

- More than 45 million hours of labor

- Nearly a million cubic yards of concrete used

- Earned 2020 Outstanding Civil Engineering Achievement Honor Award, American Society of Civil Engineers

ENGINEERING ACHIEVEMENTS

- In-The-Wet construction of the new dam, a process that involved forming the structure’s massive concrete components onshore, moving them to their required locations in the river, and installing them within extremely tight tolerances

- The world’s largest catamaran barge was used to move the massive precast concrete shells to their required location for placement on the Ohio River

- To move the concrete shells horizontally around the precast yard, the project team required the use of the second-largest gantry crane in North America