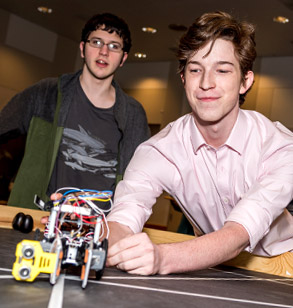

Teams ranging from Rose-Hulman Grand Prix Racing to Design-Build-Fly develop and test their latest designs before competing in national or international contests.

Hands-On Opportunities

A key feature of the Mechanical Engineering program at Rose-Hulman is the broad variety of hands-on opportunities available to students. Here, you can apply your classroom knowledge to solve real-life problems—while tackling projects you’re passionate about. Learn more below.

Individual & Group Design Projects

Whether for a class or just for the fun of it, you’ll have the faculty support, workspace, and resources to complete senior projects, experimentation, and innovation that is only limited by your imagination.

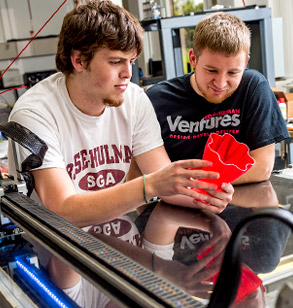

Rose-Hulman Ventures Internships

At Ventures, student interns learn to find innovative solutions for real-world clients with real-world problems. A Ventures internship will prepare you to tackle for any engineering challenge as you apply your academic studies to hands-on problem-solving.

Where Innovation Meets Application

The Branam Innovation Center is a hub of activity for student teams, humanitarian design projects and other opportunities for hands-on work. Find out more about the one-of-a-kind collaborative environment at the BIC.

Facilities & Resources

We believe the best way to learn is by doing, so we place emphasis on lab work with a hands-on approach. Our teaching, research, and MiNDs laboratories, and observatory, are stocked with modern equipment. Here, you’ll have the opportunity for hands-on undergraduate research experiences that most schools reserve for graduate students.

Branam Innovation Center

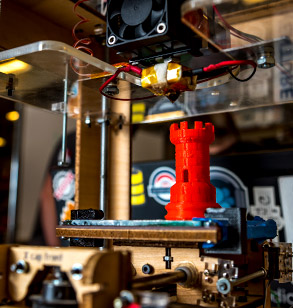

At the Branam Innovation Center (BIC) you’ll be able to practice innovation and bring your creations from concept to reality. This 16,200-square-foot open workspace is where teams huddle ahead of intense competitions, clubs unveil new innovations, and individual students tweak their latest projects.

Machine Shop

Every mechanical engineer needs to know “How’s that made?” and we bring everyone into the machine shop—beginning with EM103 Intro to Design freshman year, and again in their junior year for ME317 Design for Manufacturing. This is where you’ll learn about what you can do with saws, drills, lathes, and mills. We also have welding equipment and a plasma cutter, and offer a “Shop Badge Level I” opportunity for students who have very little experience and want to learn more in a small group (4 students/instructor). Then you’ll be ready to learn more on your own.

Manufacturing Lab

Our manufacturing lab contains most of our automated machine tools (Computer Aided Manufacturing, or CAM tools). One of our most popular electives, ME520 CAD/CAM, uses this lab to teach students about the various tools--you can get one-on-one training on the machines, as well. A large bed foam router supports our competition teams’ needs in creating molds for composite shells, and laser cutters allow us to create “links” for the EM121 Statics Link competition (freshman year).

Materials Lab

Get hands-on experience in our newly renovated Materials Lab. We use this lab for courses such as Materials Engineering and for course projects in ME Laboratory. It’s also used extensively for independent projects. Here, you can use digital microscopes to examine the effects of heating and quenching on the structure and strength of metals. Or use tensile testing equipment to find out just how much load that material can handle before it breaks, as well as machines to see how the material stands up to sudden impacts.

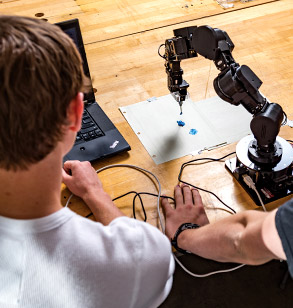

Mechatronics Lab

Robotics Lab

Dr. Richard Onyancha

Dr. Richard Onyancha specializes in manufacturing, solid mechanics and metrology. He recently spent a year as a Fulbright Scholar working at Zambia's Copperbelt University, helping the university review its engineering curricula, mentoring younger faculty members, assisting with the writing of several research proposals, and developing relationships with local industries.

Contact Us

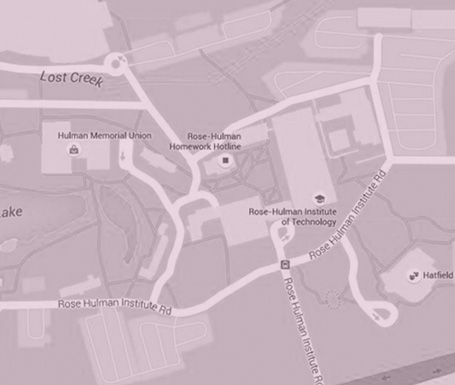

Department of Mechanical Engineering

Moench Hall C103

5500 Wabash Avenue

Terre Haute, IN 47803

812-877-8422

nicoson1@rose-hulman.edu